GIGANTEX Composite Technologies is a Taiwanese manufacturing firm specialized in producing high performance bicycle components (e.g. crank set, handle bar, wheel set, etc.) and medical equipment (e.g. spine board, wheel chair, etc.) using carbon fibre reinforced plastic (CFRP). On top of the daily engineering duties as a GIGANTEX’s R&D intern, I was assigned to explore new medical applications for CFRP material in order to kick start new business for the company. Thus, I developed a conceptual model of CFRP powered ambulance stretcher which takes advantage of lightweight CFRP material and provides added convenience of automatic patient lifting and lowering functionality. I independently analyzed competitor products to find gaps in the market and designed the stretcher’s mechanical architecture in 3D CAD environment. Following completion of the design, I also assisted the development of its intellectual property. The design eventually evolved into a commercialized product sold in the Australian market.

CFRP Powered Ambulance Stretcher

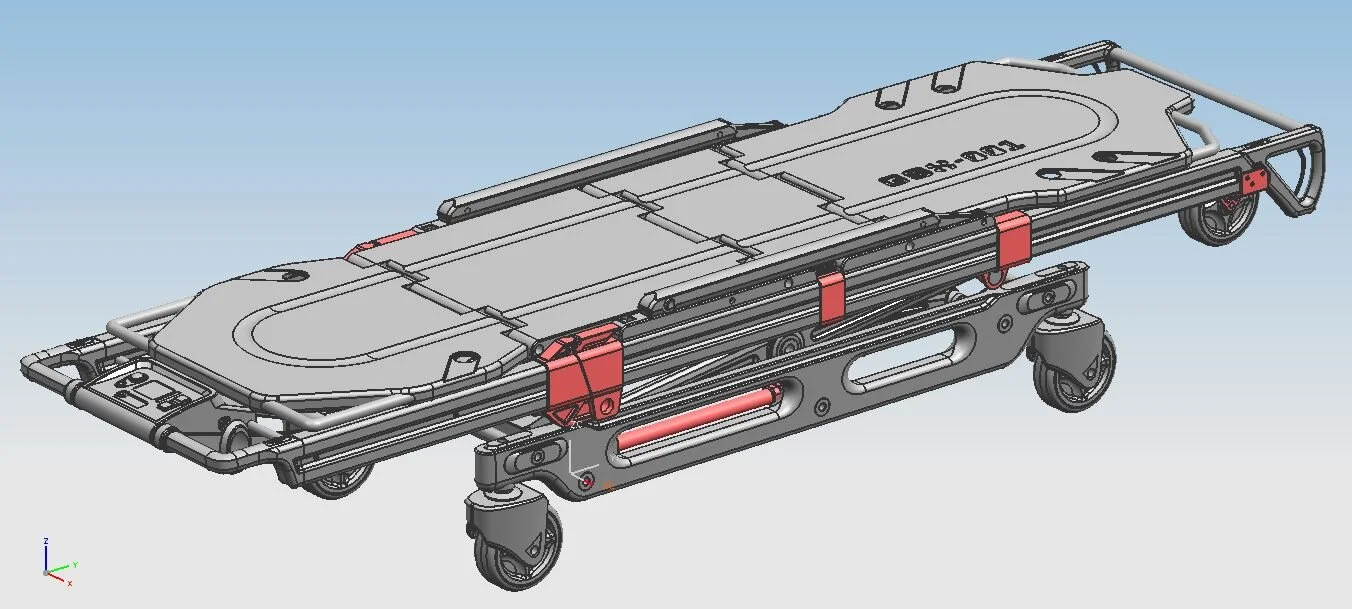

With an estimated sub-45kg weight, the proposed design was the lightest powered stretcher in its class.

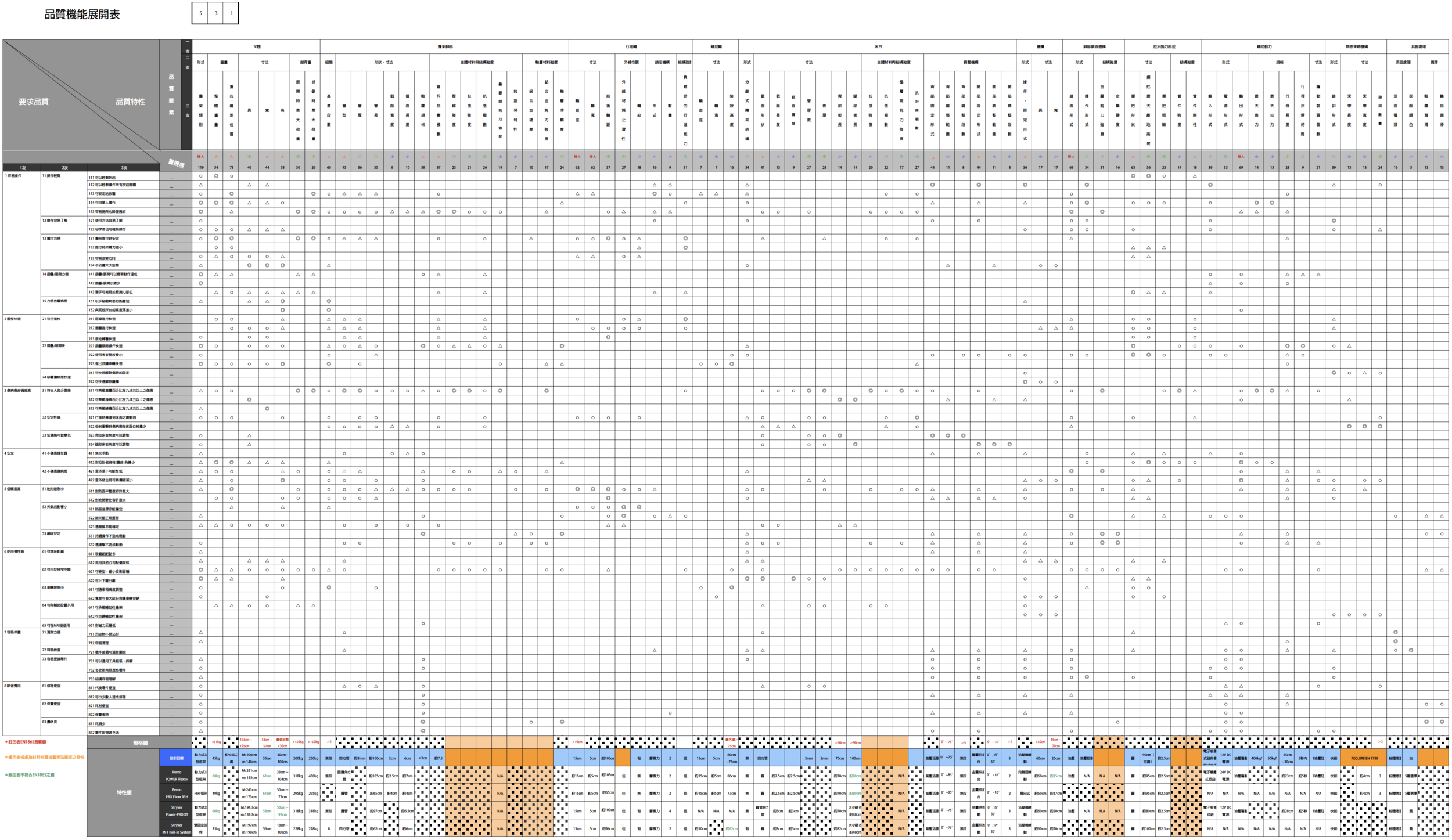

Quality Function Deployment

I used quality function deployment (house of quality) to carefully analyze the correlation between the stretcher’s engineering characteristics and needs of first responders. The analysis helps establish clear design goals for the sub-systems and the overall assembly of the stretcher.

Exploration of Legs

To an ambulance stretcher, leg folding mechanism is one of the most critical sub-assembly. The sub-assembly not only bears weight of patient and its own bed structures, but also needs to be folded and expanded with ease. Therefore I conducted in-depth analysis to find the most suitable solution from several different concepts.

Up and Down Made Easy

The stretcher utilizes a linear actuator and a scissor lift mechanism to realize automated bed lifting and lowering. This function could reduce the burden to first responders especially when rescuing patients with obesity.

The design takes advantage of GIGANTEX’s trade secret in making high stiffness-to-weight ratio CFRP parts, while it uses metal components where higher surface wear is expected (see the parts highlighted in red). GIGANTEX uses heated metal molds to cure layered CFRP prepregs, and thus there is a lot more freedom in the shape each part can take compared to metal counterparts. This allowed my I designing cross-section of each structural components differently to acquire desired mechanical property. For instance, I could introduce localized damping effect in the structure to improves ride comfort on rougher ground surfaces.

Moreover, composite material like CFRP allows designing of local material property by engineering the layering patterns, and thus further performance optimization is possible. Note that the cushioning bed surface and belts are not included in the model.

Variable Patient Positions

The stretcher is compatible with multiple patient positions, including supine, Fowler's, semi-Fowler’s, and orthopaedic positions, so the first responders could choose an appropriate one according to the patient’s medical condition.

Other Functionalities

If the condition allows, the stretcher bed frame can be folded and retracted to minimize the overall projected area. This is to improve maneuverability in tight space, which is very common in Asian countries.

The stretcher is also equipped with a foldable CFRP handle bar which the responders can use to to maneuver the stretcher when it is in the lower state.

Patented Design

In 2011, the CFRP powered stretcher design was granted a patent in Taiwan. I assisted the intellectual property agent throughout the patent application process by providing required drawings and technical summaries for key functionalities.